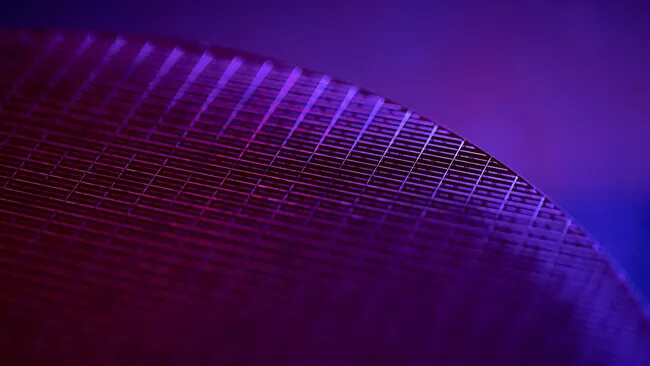

Scientists and engineers have been conducting experiments with hafnium oxide for the past decade. Many believe that this "elusive ferroelectric material" holds great potential for next-generation computing memory due to its non-volatile properties. However, achieving practical implementation requires a significant scientific breakthrough. Hafnia is naturally non-ferroelectric, so it takes effort to bring it into a suitable state. Previous efforts involved straining hafnia as a thin, two-dimensional film of nanometer thickness.

Exciting progress has been made by research teams at the University of Rochester, New York and the University of Tennessee, Knoxville. Sobhit Singh, an assistant professor at the University of Rochester's Department of Mechanical Engineering, believes that their joint effort has paved the way for the development of bulk ferroelectric and antiferroelectric hafnia.

In his study published in the "Proceedings of the National Academy of Sciences," Singh proposes an alternative material path. He highlights the practical applications of hafnia in computer technology, particularly for data storage. Currently, magnetic forms of memory are used, which are slow, energy-intensive, and inefficient. Ferroelectric forms of memory, on the other hand, are robust, ultra-fast, cheaper to produce, and more energy-efficient.

Professor Janice Musfeldt's team at the University of Tennessee successfully produced a ferroelectric form of hafnia through an experimental high-pressure process based on Singh's calculations. Even after the experiment, the material remained in a metastable phase, even when the pressure was relieved. Musfeldt commended the pleasing results as an excellent example of experimental-theoretical collaboration.

Hafnia's breakthrough potential has caught the attention of memory manufacturers. However, the high material costs are tempering expectations. According to Tom's Hardware, hafnium, the key component in hafnia, has experienced a nearly fivefold price increase due to increased demand since 2021. This has raised its cost from about $1,000 per kilogram to about $5,000. Even at $1,000 per kilogram, hafnium is significantly more expensive than silicon, which costs only tens of dollars per kilogram.